Highest quality valves for the highest requirements. Spherical disk valves (a.k.a. segmented ball valves) consists of a housing and a "segment or part" of a ball that is supported on... Read more

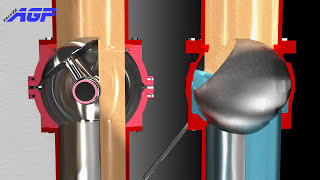

Spherical Disk (Segment Ball) Valve

Highest quality valves for the highest requirements. Spherical disk valves (a.k.a. segmented ball valves) consists of a housing and a "segment or part" of a ball that is supported on two sides by maintenance-free bearings and sealed with an inflatable or static seal. The segment can have a spherical top or flat top (for a flush mounted interior surface as required by many mixers). A 90 degree rotation of the segment allows even difficult flowing products to pass the valve’s full bore in a short amount of time. During the rotation, the segment moves freely past the spherically shaped housing. A spherical disk valve can be used both as an inlet and an outlet valve and can be used to shut a stream of flowing product.

Andocksysteme spherical disk valves are the most flexible available on the market today. As each application is different, they offer full customization for each valve.

The valves are specifically designed for clean applications such as pharmaceuticals, foods and high purity chemicals. All valves can be CIP (cleaned in place with output the need to take apart). To achieve CIP the valves are supplied with special internal CIP nozzles.

The most commonly used applications in which the spherical disk valves are used include: conical blenders, mixers and dryers, reactors, double conical dryers, horizontal blenders and dryers, agitator vessels, and in piping.

High-level equipment with high-tech components. A few characteristics that the segment ball valve distinguishes itself from other valves are: high-grade seals; vacuum and pressure tight; full bore without any restrictions; a long service life, even at high and low temperatures; CIP; no dead space in product contacted areas and a high demand of quality for product contacted surfaces.

Construction Materials:

- Housing and Disk: AISI 316L stainless steel, Hastellloy HC 22, Allow 59 or Titan,

- Seal Materials (FDA/USDA compliant): EPDM, Viton (FKM), or Perfluoroelastomer (FFKM),

- Pressure: Up to 150 p.s.i.,

All valves are supplied with material, finish and passivation certification.

Seal types: The valves are supplied with either inflatable seals or static seals. The inflatable version not only assures 100% gas and liquid sealing but also is the best solution for abrasive products which would otherwise require a metal seat or frequent seal changes (and potentially contaminate your products).

Actuation: Manual hand lever (for small valves), spring return (single acting) or double acting. Positioners can be added and the valve can also be used for dosing materials.

A Segment Ball Valve can be used both as an inlet and an outlet valve and can be used to shut a stream of flowing product. The most commonly used applications in which the Segment Ball Valves are applied are: conical blenders, mixers and dryers, reactors, double conical dryers, horizontal blenders and dryers, agitator vessels, sluices and piping.