This is the manual version of the Andocksysteme split valve technology with stainless steel support frame. All split butterfly valves consist of an active and passive valve that are supported... Read more

High Containment Valve with Frame - Active/Manual

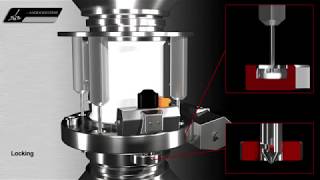

This is the manual version of the Andocksysteme split valve technology with stainless steel support frame. All split butterfly valves consist of an active and passive valve that are supported on two sides by high-grade precision bearings. The passive valve can be mounted onto the inlet or outlet of any IBC. The active valve can then be easily integrated into the filling or discharging side of any process using a wide array of available equipment options.

During docking, the GMP-designed locking pins facilitate the centering of the active and passive valves onto each other with an accuracy of ± 14 mm. The two split valves open simultaneously after docking and during the filling or discharging process the product being transferred is fully contained. The ASBV docking system is made easier and more convenient by the flexible 180º positioning of the passive valve onto the active valve.

The docking system can be mounted with a CIP dome having either a stationary or rotating CIP nozzle to bind the dust particles to prevent dust from escaping. In most cases, the parts to be cleaned (active valve with bellows) are removed from the process station using a suction pad without any need to disconnect the hoses and cables from the actuators or controls.

With the need for ever-shorter downtimes, production can be resumed after only five minutes simply by installing another active valve, saving both time and money.

PTFE Seals

A high containment system is only as good as the seals that are used. Ultimately, the sealing materials determine the containment levels achieved.

The

PTFE seals used with our valves offer outstanding thermal and chemical resistance properties, while retaining stringent containment levels. This ensures

that the valve is even capable of handling the expansion and contraction of the metal parts during the thermal sterilization (> 121ºC) that aseptic

processes typically require.

Innovative, new PTFE production techniques, combined with an encapsulated elastomer core, ensure that the finished seal will also meet the highest containment requirements in demanding process pressure and vacuum conditions.

This new manufacturing process results in a seal with a smooth, polished surface, where powder retention is virtually eliminated.

PFTE Seal Properties:

- Chemical resistance

- Broad temperature range (-250ºC to +260ºC)

- FDA-approved material

- Very low coefficient of friction

- No absorption of water

PTFE Seal Advantages:

- Cost savings compared to traditional elastomer seals

- Sterilization in place (SIP) of docked split-valves is possible

- Suitable for high containment powders and liquids charging

- Suitable for chemically aggressive powders and liquids

- PTFE does not shed seal material into the product

- Less than 1 μg/m3 containment levels are achievable