The Servolift Universal Drum Clamping System is the cleanest, strongest and most reliable drum handling system available on the market. The system works by pressing the drum into a fixed... Read more

Drum Lifter Universal

1.0 MB

Drum Lifter - Universal

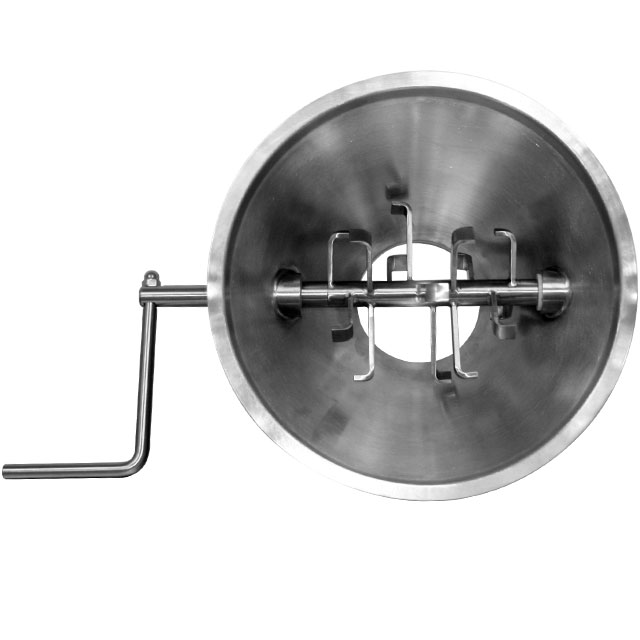

The Servolift Universal Drum Clamping System is the cleanest, strongest and most reliable drum handling system available on the market. The system works by pressing the drum into a fixed funnel forming an airtight seal for dust-free, ergonomic transfer of the drum’s products. True to its name, the system can handle any drum type or size for total flexibility. As with all Servolift equipment, we customize each system to meet your particular application.

Typical Applications (loading):

- Tablet Presses

- Weigh-off / dispensary drum emptying

- Mixing tanks

- Reactors/Compounding Tanks

- Mills

Design Capabilities:

- Lifting Capacity to 1,500 lbs

- Battery Power, Pneumatic or Plug in Electric

- Manual push or Powered Drive

- Lifting Heights to 216" (higher on request)

- Overhang (reach) to 72"

- Clamping of any drum type (fiber, plastic or steel)

- Explosion proof for all classes and divisions

- Full Washdown

- Stainless Steel 304 or 316L

- Any level of finish

- Load Cells can be installed into the arm system

- 100% customizable for any possible application!