Servolift Drum Lifters with Manual Clamping are a simple solution for handling our stainless steel drums or any other type of drum you have. Clamping is from our solid stainless... Read more

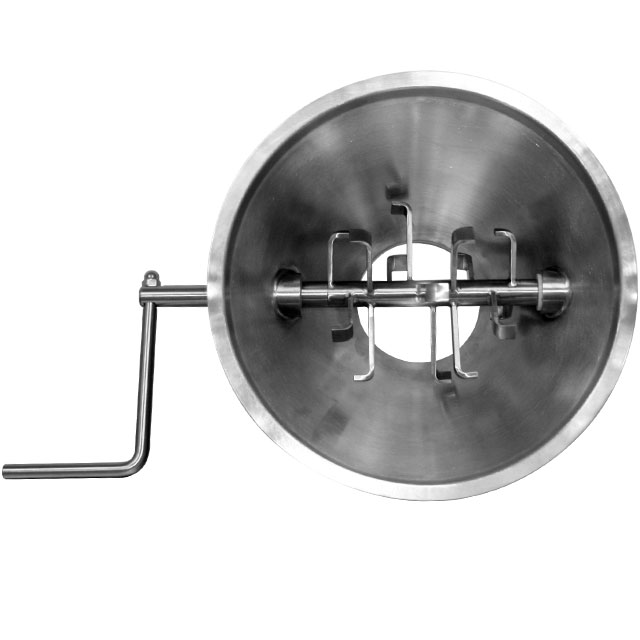

Drum Lifter Manual Clamp

468 KB

Drum Lifter - Stationary

Servolift Drum Lifters with Manual Clamping are a simple solution for handling our stainless steel drums or any other type of drum you have. Clamping is from our solid stainless steel 360° clamp with dual safety lockings. The system is also well suited to high accuracy handling when using Split Butterfly Valves.

Typical Applications (loading):

- Tablet Presses

- Encapsulators

- Mixing tanks

- Reactors/Compounding Tanks

- Mills

- High Shear Granulators

- Design Capabilities:

- Lifting Capacity to 1,500 lbs

- Lifting Heights to 60'

- Overhang (reach) to 12'

- Can be free standing, hung from the ceiling or attached to both ceiling and floor

- Explosion proof for all classes and divisions

- Cleanroom ready to Class 100

- Full Washdown

- Stainless Steel 304 or 316L

- Any level of finish

- Controls offered from simple pneumatic to fully automated PLC/HMI operation

- 100% customizable for any possible application!

- Optional Load Cells can be installed into the arm system