Need Assistance? Call us at (973) 442-7878 or email us.

Serving the U.S., Canada & Puerto Rico

Stationary Drum Handlers

4 Products

Drum Lifter - Stationary

Servolift Drum Lifters with Manual Clamping are a simple solution for handling our stainless steel drums or any other type of drum you have. Clamping is from our solid stainless steel 360° clamp with dual safety lockings. The system is also well suited to high accuracy handling when using Split Butterfly Valves. Typical Applications (loading): Tablet Presses Encapsulators Mixing tanks...

Drum Lifter - Universal

The Servolift Universal Drum Clamping System is the cleanest, strongest and most reliable drum handling system available on the market. The system works by pressing the drum into a fixed funnel forming an airtight seal for dust-free, ergonomic transfer of the drum’s products. True to its name, the system can handle any drum type or size for total flexibility. As...

Drum Nests

SERVOLiFT drum nests offer a cost effective solution to handling and discharging drums. With a nest installed above every discharge point (such as a screener or tablet press), load the drum/funnel into the nest and remove the mobile lifter from the area to service another nest system...one lifter can do the work of 5 or more stationary lifters! Servolift hygienic...

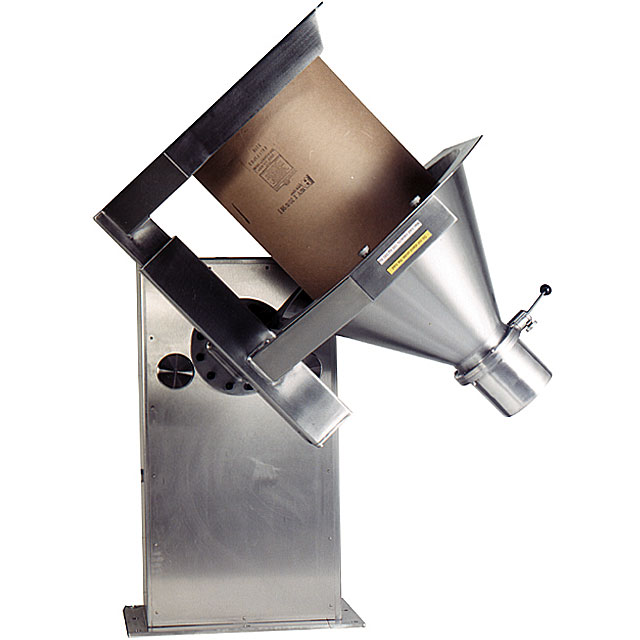

Drum Tipper - Stationary

Servolift drum tippers for every size and type of drum on the market. We have built hundreds of these machines for every possible application. Design Capabilities: Lifting Capacity to 1,500 lbs Can automatically handle multiple drum sizes and types Free standing, pedestal style Explosion proof for all classes and divisions Cleanroom ready to Class 100 Full Washdown Stainless Steel 304...